2. Güvenlik Kapalı bir yapıya sahip olması, hırsızlık ve zarar görme riskini azaltır.

- When it comes to electrical work, safety is paramount. One of the most important tools in an electrician's toolkit is insulation tape, and when it comes to choosing the right color, blue insulation tape stands out for its versatility and effectiveness.

- Black

- One of the key benefits of using blue insulation tape is its ability to withstand high temperatures. This makes it an excellent choice for use in applications where wires and cables are subjected to extreme heat, such as in automotive engines or industrial machinery. The tape's ability to maintain its insulating properties even at high temperatures ensures that electrical systems remain safe and reliable.

- In addition to its insulation properties, PVC insulation tape black is also highly flexible and easy to work with. It can be easily torn by hand, making it convenient for on-the-go applications. Its adhesive backing ensures a secure hold on the wires, allowing for a reliable and long-lasting connection.

- In conclusion, butyl rope caulk is a versatile, durable, and easy-to-use sealant that offers unparalleled protection for your home. Its exceptional weatherproofing properties, ease of application, and aesthetic appeal make it an indispensable tool for anyone engaged in home improvement or maintenance. So why wait? Grab a roll of butyl rope caulk today and start enjoying the many benefits it has to offer!

J50 High-voltage EPR Rubber Tape

how to use self amalgamating repair tape. Make sure to overlap the tape as you wrap it around to ensure a secure bond.

Another benefit of Flex Tape Waterproof Clear is its transparency. Unlike traditional tapes that are often opaque and bulky, Flex Tape Waterproof Clear is almost invisible once applied. This makes it perfect for projects where aesthetics are important, such as repairing a glass surface or fixing a clear plastic window.

flex tape waterproof clear

Rubber tapes are an essential component in many industries

5. Easy Application Applying self-fusing rubber tape is straightforward. It can be easily wrapped around wires or surfaces without requiring special tools or adhesives. Once layered, the tape fuses to itself, providing a snug fit that ensures effective insulation and protection.

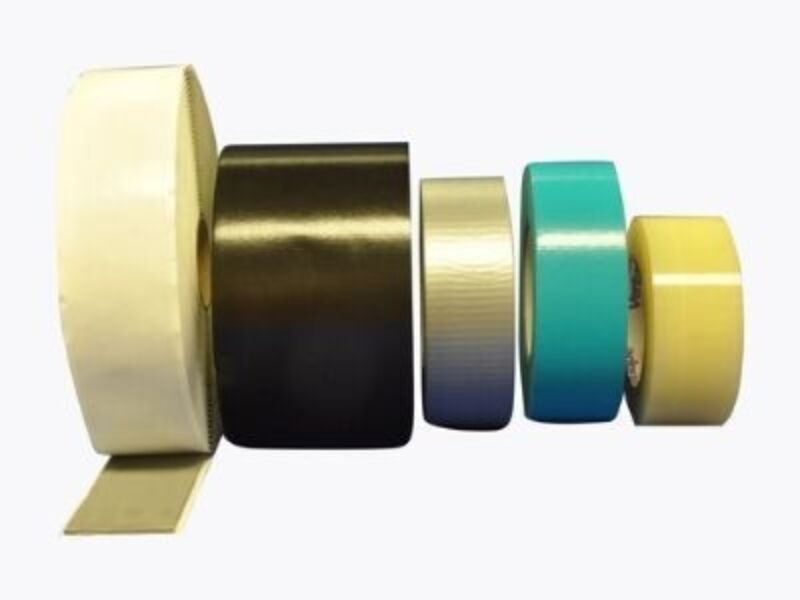

Choosing the Best Type of Tape for the Job

In a typical tape splice, you’ll tug and pull out the tape, stretching it to just before the breaking point. The tape’s width narrows to about 1/3rd of its original size. The tape’s length increases; your hand travels very quickly up to 20” away from where you started. Quite often you’ll be wrapping in a tight location making this even more difficult. Proper taping techniques are critical to realizing the many performance benefits of rubber tape.

How does silicone tape work?

It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection

It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection brown insulation tape. It's also invaluable for temporarily repairing damaged cables or insulation, providing a quick fix until a more permanent solution can be implemented.

brown insulation tape. It's also invaluable for temporarily repairing damaged cables or insulation, providing a quick fix until a more permanent solution can be implemented.